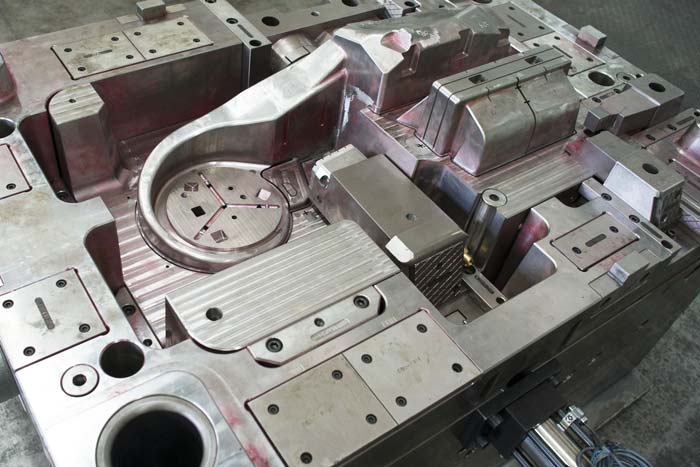

Polishing Treatment for Plastic Molds

Polishing Treatment for Plastic Molds With the widespread application of plastic products, such as daily-use items and beverage packaging containers, there is often a requirement

When the surface quality of plastic parts fails to meet the design requirements due to weld lines, technicians usually start with the melting material temperature, injection speed, pressure, flow rate, mold temperature, etc. to solve the problem. And all of these can be realized through equipment, with small adjustments referring to the injection molding conditions and standards, approaching the ideal value.

Obviously, items that can be adjusted through equipment such as melt temperature, flow velocity, pressure, flow rate, and mold temperature are relatively easy to achieve. On the one hand, it is convenient to adjust, on the other hand, it can be repeated many times. However, the difficulty lies in: when the above means can no longer solve the problem, it is necessary to modify the mold to achieve the expected effect, which is also the focus of discussion.

The following situations may require injection mold modification:

(1) There are air bubbles in the weld line, and it is necessary to add a vent hole on the corresponding parting surface.

Causes of bubble formation:

When the two melts converge, the surrounding gas is not removed in time. But it remains inside the plastic part, forming pits on the surface of the weld line. It can also be commonly called “trapped air” .

(2) The depth of the weld line is always out of tolerance, and it is necessary to adjust the thickness of the plastic part, that is, the mold cavity.

Reasons for the depth difference:

The reason may be that the parting surface at the corresponding position is too tight, so that the gas cannot be discharged. It may also be caused by excessively uneven height and dimension of the cavity after mold closing (the wall thickness of the plastic parts is quite different).

(3) The position of the weld line is biased towards the middle of the plastic part, and the position of the gate needs to be adjusted.

In view of the former situation, it is often improved by adding or enlarging the exhaust groove. Taking the PP material which is the most widely used in China as an example, according to the parameter that the overflow gap of the PP material is 0.03 mm. In order to avoid flashing caused by overflow, the ideal clearance of the exhaust groove is 0.01~0.02mm.

In order to facilitate the cleaning of the cavity during the mold processing and molding process, the position of the exhaust groove will be selected to be opened on the parting surface of the fixed mold in most cases. And it should be opened at the last filling part of the cavity as much as possible.

For the situation where the cavity height is too uneven, the cavity size can only be adjusted by “repair welding” and “grinding”, which is the most difficult. The adjustment method is the same as the adjustment method that the weld line height is always out of tolerance to be mentioned below.

When the poor quality of plastic parts due to weld lines cannot be improved or eliminated by adjusting the process parameters of the equipment and opening the exhaust groove, it is likely to have to adjust the size of the cavity. Of course, it is necessary to accurately measure the thickness of the corresponding part of the plastic part, and then work within the range allowed by the design.

The wall thickness of the bumper plastic part is not equivalent in different parts, but a gradual amount. Considering the specific shape of the plastic part and the fluidity of the molten plastic, the gradual wall thickness is conducive to molding. The wall thickness is usually 2.60~3.50mm.

There are two cases of modification of mold cavity size:

① Increase the size of the cavity, which is easier to implement. According to the detection data, directly polish the corresponding parts of the mold cavity.

② Reduce the size of the cavity, which is more complicated. In order to achieve the purpose of reducing the size of the cavity, it is first necessary to surfacing welding on the surface of the cavity of the mold, and then grinding.

The following is a detailed introduction to the method of reducing the size of the mold cavity:

It is much easier to choose “repair welding” and “grinding” on the moving mold than on the fixed mold.

Since the quality of the fixed mold cavity surface of the injection mold directly affects the appearance of the plastic part, and a large amount of heat is generated during the welding process. Without adequate process measures, these heats will often change the composition of the cavity surface, resulting in different hardness of the cavity surface. Further, it will affect the appearance of the plastic part. In practice, it is necessary to avoid modification of the cavity surface of the fixed model as much as possible.

The general steps to modify the cavity surface of the dynamic model are as follows:

① Test the mold by pasting glue on the surface of the cavity, and roughly get the thickness of the cavity that needs to be increased or decreased.

② Implement “repair welding” and “grinding” operations.

The second step is the difficulty and key point, the following is the detailed process of cavity surface repair:

③ Try the mold again, and adjust the size of the cavity surface according to the molding effect.

Polishing Treatment for Plastic Molds With the widespread application of plastic products, such as daily-use items and beverage packaging containers, there is often a requirement

Injection Molding Techniques for TPE and TPR Injection Molding Techniques for TPE and TPR 1. Dry the TPE and TPR material before injection molding It

Winter Maintenance Measures for Injection Molding Machines As winter approaches and temperatures gradually drop, a cold chill envelops the earth. While ensuring personal warmth, it

Assessment Regulations for Mold Trial Exceeding 3 Times Assessment Regulations for Mold Trial 1. Purpose The purpose of this regulation is to standardize the work of