Cable Tie Injection Molding Machine

We began to produce cable tie injection molding machines in 2005, with years of experience, we have obtained more than 60% market share in China.

KF serires: 288T, 358T and 428T, mainly for cool runner mold

KL serires: 500T, 650T, 850T and 1000T, mainly for hot runner mold

We have turn-key project ability for the oversea market and we have already helped many clients from many countries to establish their plants for cable tie manufacture.

We provide not only the injection molding machine, but also our experience from 2005 to assure the success of our clients, more topics and information about cable tie manufacturing are disscussed in our blog.

KF series – special for cable tie

Specification data are subject to change without prior notice.

KF series machines are special for the cable tie production, they have three models: 288 ton, 358 ton, and 428 ton. Their power system is with variable displacement pump.

# Injection Unit

- Integral injection unit design, high rigidity, deformation, stable injection.

- Spring nozzle preventing from drooling.

- Special screw and barrel design according to nylon character, considering the gas exhaust and water drainage guarantees the good quality product.

- Hopper on movable slide for easy cleaning.

# Clamping Unit

- All stress bearing parts with special design of high rigidity and high intensity, greatly improve the mechanical fatigue strength and guarantee the durability.

- Optimized five-point toggle design for short opening stroke achieves high production efficiency.

- Rectangular platen design satisfies the slim mold of the cable tie.

- Central oil automatic lubrication system for clamping unit.

- Manual pump of grease lubrication facilitate the lubrication request.

- Hydraulic motor drive gear for mold adjustment.

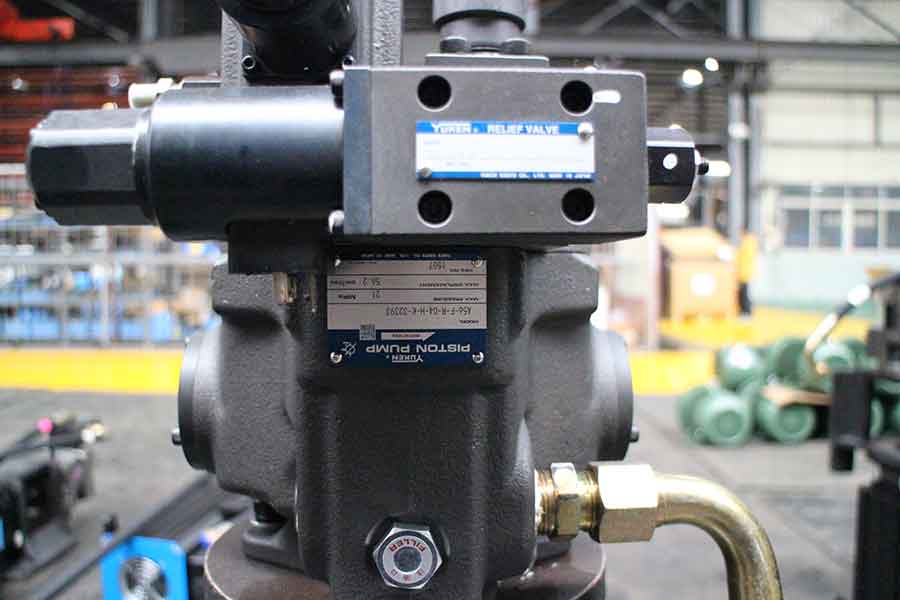

# Power System

- adopt “Yuken” high response variable displacement pump imported from Japan, obtaining stable, reliable, energy saving and easy-maintaining performance.

- The output of power system responds exactly the request of the production, avoiding the overflow loss and realizing 25% to 70% power saving comparing the traditional machine.

- Upgraded power system improves the product quality and increase the production output.

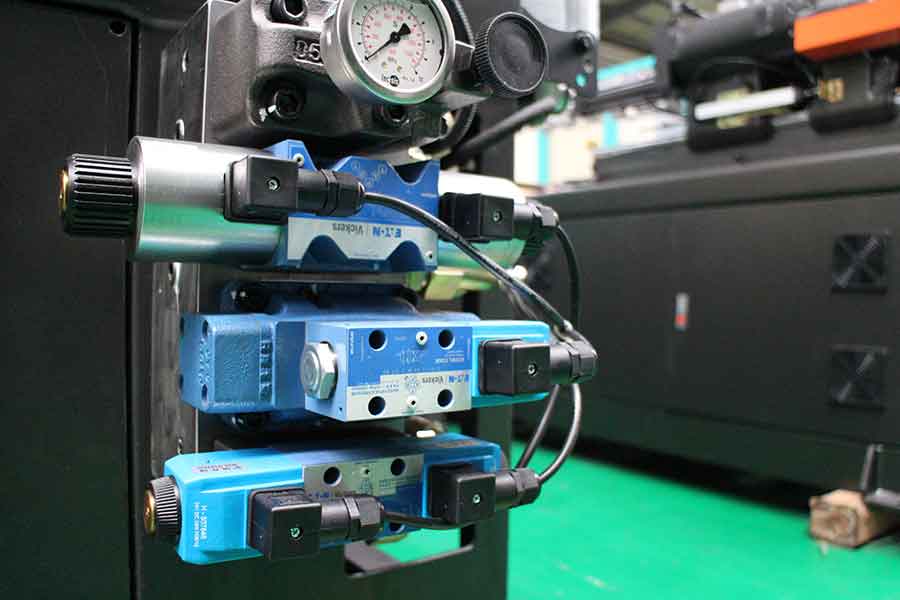

# Hydraulic System

- Optimized hydraulic circuit design satisfies the request of high pressure and high speed while minimizing the hydraulic shock.

- Reliable four layers high pressure hoses for the connection, reducing the impact.

KL series – special for cable tie

Specification data are subject to change without prior notice.

KL series machines are special for the cable tie production, they have four models: 500 ton, 650 ton, 850 ton and 1000 ton.

# Injection Unit

- The injection movement by twin cylinders for stable and reliable.

- Integral injection unit design, high rigidity, deformation, stable injection.

- Barrel support against bending caused by the gravity increases the duration.

- Special screw and barrel design according to nylon character, considering the gas exhaust and water drainage guarantees the good quality product.

- Hopper on movable slide for easy cleaning.

# Clamping Unit

- All stress bearing parts with special design of high rigidity and high intensity, greatly improve the mechanical fatigue strength and guarantees the durability.

- Optimized five-point toggle design for short opening stroke achieves high production efficiency.

- Rectangular platen design satisfies the slim mold of the cable tie.

- Central oil automatic lubrication system for clamping unit.

- Manual pump of grease lubrication facilitate the lubrication request.

- Hydraulic motor drive gear for mold adjustment.