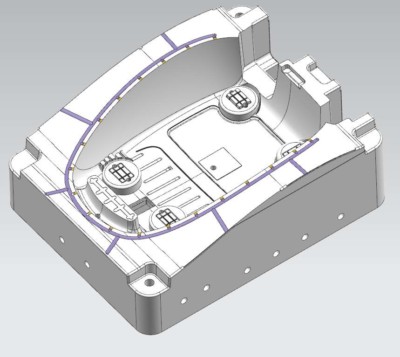

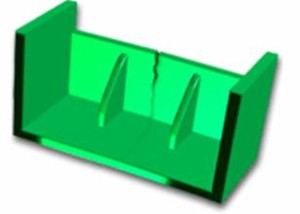

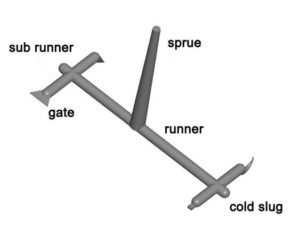

How to Deal with the Short Filling of Products During Injection?

How to Deal with the Short Filling of Products during Injection? The short filling of glue is a common problem, but it’s not difficult to solve. When technical means can’t solve the problem, it can be improved by the design and manufacture of molds. Tips: When such problems occur, it is necessary to observe the … Read more