Key Points for New Mold Test

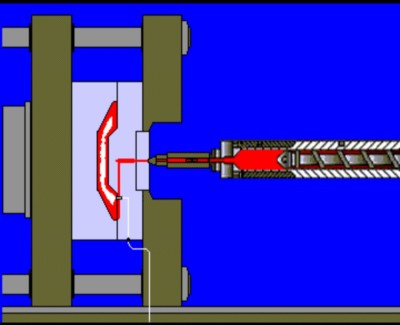

Key Points for New Mold Test About new mold test 1. Test steps A. Before testing the mold, check whether the mold is assembled and whether the raw materials are dried. B. Before changing the mold, spray the mold with anti-rust agent. Then, replace the mold and return to its position. Finally, fill in the record form. … Read more