Polishing Treatment for Plastic Molds

Polishing Treatment for Plastic Molds With the widespread application of plastic products, such as daily-use items and beverage packaging containers, there is often a requirement

The need to produce small and light parts has made thin-wall injection molding the most in-demand performance for injection molding machines. “Thin wall” usually refers to the wall thickness of less than 1mm of the lightweight electronic parts. For large automotive parts, the “thin wall” can be 2mm. In short, thin-walled products require changes in processing technology. They are higher pressure and speed, shorter cooling time, changes in product ejection and gate arrangement. The following are the requirements of thin-wall injection molding for injection machines and molds.

Standard injection machines can produce a variety of thin-walled products. The performance of the current new injection machine greatly exceeds that of 10 years ago. Advances in materials, gate technology and design have further broadened the performance of standard injection machines for filling thin-walled parts. However, due to the continuous reduction of wall thickness, a more special injection machine with high speed and high pressure performance is required. For example, for an electronic part with a thickness of less than 1mm, it is normal for the filling time to be less than 0.5 seconds and the injection pressure to exceed 210MPa.

As for the injection volume, large-diameter barrels are often too large. The recommended injection volume is 40% to 70% of the barrel capacity. And the overall molding cycle of thin-walled products is greatly shortened. It is possible to reduce the minimum injection volume to 20%~30% of the barrel capacity. Users must be very careful when injection molding is conducting. Because for the material, a small injection volume means that the material stays in the barrel for a longer time. And this will lead to a decline in product performance.

Speed is one of the key factors for the success of thin-wall injection molding. Rapid filling and high pressure can inject molten thermoplastic material into the cavity at high speed, thereby preventing the gate from freezing. If a standard part is filled within two seconds, the mold thickness is reduced by 25%. Besides, it is possible to reduce the filling time by 50%, which is exactly 1 second.

One of the advantages of thin-wall injection molding is that when the thickness is reduced, less material needs to be cooled. As the thickness decreases, the molding cycle can be shortened by half. The reasonable setting of the melt conveying device makes the hot runner and sprue not hinder the shortening of the molding cycle. The use of hot runners and sprue bushings helps to shorten the molding cycle to the minimum.

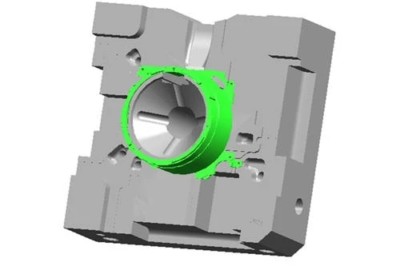

In addition, we should also consider the mold material. P20 steel is widely used in the molding of traditional products. But due to the higher pressure of thin-wall injection molding, the mold must be very strong. H-13 and other hard steels add an extra safety factor to thin-walled molds. However, the cost of a solid mold may be 30%-40% higher than that of a standard mold. But the increased cost is usually offset by improved production performance.

Polishing Treatment for Plastic Molds With the widespread application of plastic products, such as daily-use items and beverage packaging containers, there is often a requirement

Injection Molding Techniques for TPE and TPR Injection Molding Techniques for TPE and TPR 1. Dry the TPE and TPR material before injection molding It

Winter Maintenance Measures for Injection Molding Machines As winter approaches and temperatures gradually drop, a cold chill envelops the earth. While ensuring personal warmth, it

Assessment Regulations for Mold Trial Exceeding 3 Times Assessment Regulations for Mold Trial 1. Purpose The purpose of this regulation is to standardize the work of