Bicolour Injection Molding

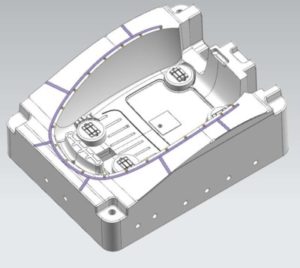

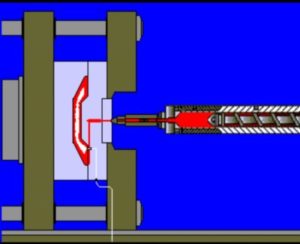

Bicolour Injection Molding | Manufacturing Process Characteristics and Mold Structures The Characteristics of Bicolour Injection Molding Manufacturing Process 1. Two sets of plastic injection devices

As an experienced and professional injection molding machine manufacturer, we can always be at the forefront of the plastic industry, grasp the latest information and the most advanced technology and equipment in the industry. In this page, we will share you some of the latest news in the plastic industry, the efficient injection molding technology and so on.

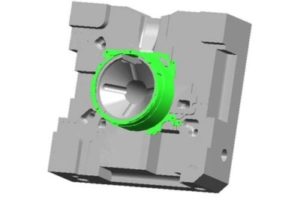

Bicolour Injection Molding | Manufacturing Process Characteristics and Mold Structures The Characteristics of Bicolour Injection Molding Manufacturing Process 1. Two sets of plastic injection devices

Points That Need to Be Confirmed When Using Steel for Injection Molds There are 6 points that need to be checked when using steel in

How to Improve the Transparency of PP Products Ways to improve the transparency of PP products 1. The matrix resin itself The transparency of the

How to Increase the Gloss of the Injection Molding Products ? Processes and Molds Ways to improve the gloss of injection molding products This article

Injection Molding Parameter | Rules for Speed Segmentation About the speed segmentation The injection speed is a key parameter of injection molding for its close

Management of Injection Mold Mold management can be roughly divided into 3 different parts. That is mold development, mold use and mold maintenance. Therefore, for the effective

Key Points for Achieving the Precision Injection Molding of LSR Precision Injection Molding of LSR There are many differences between the processing of LSR and traditional

Injection Mold Maintenance What are included in injection mold maintenance? As the most important production tool of the injection molding factory, the injection mold determines

The Application of High Rate of Fire When to use high rate of fire? When filling the mold at low speed, the flow rate and

Why Adding Glass Fiber to the Plastic Parts ? About the floating fiber Plastic parts have many shortcomings in the using process. To make plastic

The Damage and Maintenance Measures of Mold Products Maintenance measures of mold products Test the properties of injection mold We should test the various properties

About the Operation of Injection Molding Machine Tips for injection molding machine operation Before booting Check whether there is water or oil in the electrical

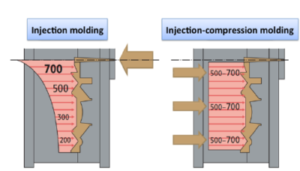

Injection Compression Molding Technology What is the injection compression molding technology? Injection compression molding (icm) is an advanced form of traditional injection molding. It can increase

How to Deal with the Vibration and Noise of Hydraulic System? Reasons for the vibration of hydraulic system Vibration and noise of hydraulic equipment mainly

How to Achieve Flame Retardant Modification of Modified Plastics? The application of modified plastics in home appliances, electronic appliances, automobiles and other fields often requires

Major Hazards and Solutions of Excessive Temperature Rise of Injection Molding Machine # Major hazards of excessive temperature rise of injection molding machine 1. Thermal

The Requirements of Thin-wall Injection Molding for Injection Machines and Molds The need to produce small and light parts has made thin-wall injection molding the

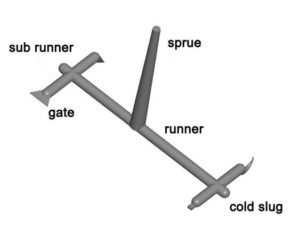

The Design of Main Runner in Injection Mold The use of the main runner design In the mold design process of plastic injection molding, it is necessary to

Analysis of Factors Affecting Precision Mold Injection Precision mold injection will be affected by many related factors and environmental conditions. And the most basic are

About the Five General Plastics Plastic is a polymer compound that is polymerized by addition polymerization or polycondensation reaction with monomer as raw material. It

The Reasons of the Demoulding Difficulty of Plastic Injection Mold After the plastic part is injection molded, the plastic part is ejected from the mold

How to Deal with the Short Filling of Products during Injection? The short filling of glue is a common problem, but it’s not difficult to

Why Should the Injection Mold Be Equipped with An Exhaust System ? The exhaust of injection mold is an important issue in mold design. Especially

Solution to the Color Problem of Injection Molded Products Causes of uneven color of injection molded products The main reasons and solutions for the uneven

How to Choose the Screw of Injection Molding Machine? As we all know, the “screw plasticizing component” is the main core unit of the injection

How to Solve the Cracks on the Surface of Injection Molded Products? Reasons and solutions for the molding cracks 1. The residual stress is too

Process Principle and Requirements of High-gloss Injection Molding Process principle of high-gloss injection molding The mold is heated before and during mold clamping. After completing

Service Life of Plasticized Components of Injection Molding Machine Brief introduction of Plasticized Components Plasticized components includes screw, melt barrel, rubber head, rubber ring, rubber gasket. When

Analysis and Countermeasures of Poor Gate Cutting Poor gate cutting It refers to a phenomenon in which the gate connecting the molded product, the main runner,

Advantages of Using Small Gates for Injection Molding Introduction of the Small Gate The gate is a critical section of the material flow channel in

Important Points of Injection Molding Machine Barrel The barrel and screw constitute the extrusion system. Like the screw, the barrel also works under the conditions

Key Points for New Mold Test About new mold test 1. Test steps A. Before testing the mold, check whether the mold is assembled and whether

About the shortcomings of injection molded parts 1. Description of shortcomings It refers to the injection molded parts that cannot meet the quality requirements of the original

The Main Plastic Properties Related to Injection Molding Processing The Main Plastic Properties 1. Liquidity The ability of the plastic in the molten state after

Light Line in the Gate Area of the Injection Molded Product In the point gate design of the vertical part direction, a radiation system appears

Application and Process of Gas-assisted Injection Molding 1. The principle of gas-assisted injection molding High-pressure inert gas (nitrogen) is injected into the molten plastic to form a

5 Effects of Mold Temperature on Quality Control of Injection Molded Parts Mold temperature refers to the surface temperature of the mold cavity in contact

The Processing Principle of Gas-assisted Injection Molding System The gas-assisted injection molding system directly injects nitrogen into the plasticized plastic in the mold cavity through

About the Design of Gas-assisted Injection Products Gas-assisted injection molding technology is an emerging plastic injection molding technology. Its principle is to use high-pressure gas

How to Increase the Brightness of ABS Injection Molded Parts? The reasons for poor gloss of plastic parts can be considered from mold, injection molding

The Types of Plastic Molding and Processing 1. Injection molding The plastic material is first heated and melted in the heating barrel of the injection

Mold for and Shrinkage Problems in Precision Injection Molding 4. Shrinkage problems in precision injection molding There are four factors that affect shrinkage: thermal shrinkage,

Features and Selection of Precision Injection Molding Machine 3. Features and selection of precision injection machine 3.1 Features in technical parameters According to injection pressure,

The Concept of Precision Injection Molding and Selection of Materials 1. Concept When general injection molding machines and conventional injection molding processes can’t meet the requirements

Black Spots on Injection Products | Possible Causes This is an analysis of the possible causes of black spots on injection products. Causes of black

How to Ensure the Safety When Operating Injection Molding Machine? The operating procedures of the injection molding machine 1. Familiar with the operation of injection

Causes of Silver Streaks in Injection Molding 1. Phenomenon of silver streaks A phenomenon in which silver streaks occur on the surface of a molded product. 2.

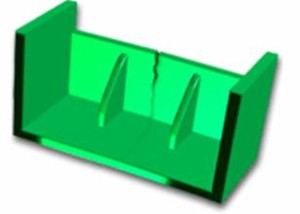

Notes for Multi-material Injection Molding Over injection molding, like co-injection molding, bicolor injection molding and sandwich injection molding, belongs to multi-material injection molding technology. The

Preparations Before Injection Molding In this article, we will discuss the preparations before injection molding. So the following steps are indispensable for the quality of

The Advantages And Disadvantages About Hot Runners Advantages of Hot Runners 1. Shorten cycle time The molding cycle is shortened. There is no restriction on

Cable Tie Sourcing Service in China 1. How to Inspect your Cable Tie? 1.1 Look 1.2 Listen 1.3 Check by Tensile Strength Machine. 1.4 Use

What Are the Important Parameters of the Injection Molding Process? Because the injection molding equipment and the requirements for product quality continuously develop. Higher requirements

Mold Temperature Controller, Water Type or Oil Type? Mold temperature controller is a small equipment used for heating the connected mold to obtain the correct

Machine Features and Functions Clamp Unit Injection Unit Others Clamp Unit 1. Electric Door required for large machine 2. Copper Tube Lubrication 3. Blowing When

Some Spare Parts for Injection Molding Machine Spare Parts shock-proof-feet heating-winding check-seat nylon-tube check-ring screw-tip toolkit ( including: test pencil, socket head wrench, screwdriver (

Common Problems About the Plastic Equipment Frequently asked questions about plastic equipment. 1. EU12 Robot Connection 2. Setting Lubrication Modulus (1) change screen from “operator”

Cable Tie Mould – Guide of 2023 All issues about cable tie mould: cable tie mould drawing, cable tie mould manufacturing process with photos and

Cable Tie Manufacturing Equipment The collections for the cable tie plant equipemnts, including cable tie injection molding machine, cable tie mold, and all the auxiliary

Cable Tie Manufacturing – by Bill Huang This article is introducing the Manufacturing of Cable Tie from three aspects: injection molding machine special for cable